Flex Films launches F-UHB-M – a metallic polyester ultra-high barrier film

Flex Films, the global film manufacturing arm of flexible packaging giant UFlex, has launched its new avant-garde patented BOPET high barrier pic F-UHB-M, designed to supplant aluminum foil in flexible packaging applications. According to the press release datelined Kentucky, Us, 23 September 2021, the new film will be manufactured in the Flex Films Kentucky plant and supplied worldwide.

F-UHB-M addresses the converting industry's challenges that take relied on aluminum foil for packaging for a long time. Amongst foil's limitations are its availability, high material cost, weak integrity, propensity for in-employ pinhole germination, and difficulty in recycling.

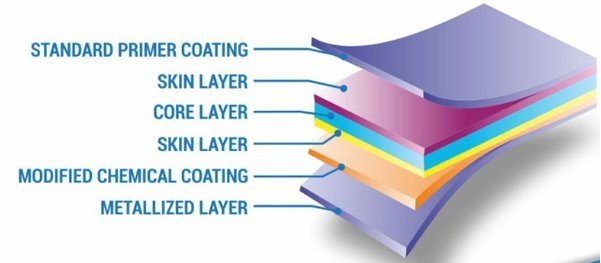

With its new specially formulated bi-axially oriented polyester (BOPET) structure, F-UHB-Grand provides superior gas and h2o barrier – achieving one of the lowest oxygen and moisture barrier values (0.1 cc/ m2-24-hour interval & 0.1 gm/m2-twenty-four hours, respectively). The new structure'southward industry-leading metal adhesion of 1200 gm/25mm aids improvement and extension of product shelf-life. Barrier operation is retained after incorporating F-UHB-M into a multi-layer laminate structure, demonstrating splendid handling, machinability, and resistance to pinhole formation.

Flex Films' new film will be shown to manufacture visitors at Pack Expo 2021, at the Las Vegas Convention Centre from 27 to 29 September 2021, at the Flex Films stand up North-9115. The new F-UHB-Thou motion picture has a thickness of 12 microns. Its coating engineering and a very high optical density are compatible with a wide range of inks and adhesives. In add-on, it has better machinability and handling during processing. Flex says information technology comes with practiced flex fissure resistance and has 20% increased puncture resistance vs BOPET grades.

Furthermore, an advanced in-line inspection machinery in its manufacture ensures consistency in bulwark properties and far less pinhole density than aluminum foils, making information technology less susceptible to gas and h2o vapor leakages. In add-on, it generates less fleck during production. These attributes requite the new BOPET film a robust competitive border making it suitable for flexible packaging applications dominated by a laminate comprising of aluminum foil.

From 4-ply to a more straightforward 3-ply laminate structure

F-UHB-Thousand offers multiple benefits ranging from cost-efficiency, a higher sustainability quotient, and efficient use in logistics and eCommerce. For example, one of the biggest challenges that the packaging motion picture industry faces today is reducing nutrient wastage through enhanced shelf-life of food products and reducing packaging cloth consumption through laminate rationalization.

The F-UHB-M laminate tin assistance the converting industry move from a 'difficult to recycle 4-ply laminate structure with aluminum foil' to a 'much simpler, easily recyclable three-ply laminate structure. Moreover, it can be done without compromising barrier performance, thus helping the client achieve reduced laminate weight and lower price with a minimized carbon footprint.

While the new loftier barrier film's protective oxygen and moisture barrier assist lock in the flavor and odor of food products for longer than products packaged in aluminum foils, the high metal bond forcefulness ensures against delamination. This makes the laminate more than secure and the product safer while retaining its quality. These advantages can help eCommerce logistics over long distances without damaging consumer food products.

The materials cost of F-UHB-Chiliad is less impacted by toll fluctuations than aluminum foil, allowing better cost forecasting. Thus, with a better yield per unit area, F-UHB-M will likely prove to be a highly cost-constructive film.

The FDA-compliant film also suits applications in medical packaging, dried and powdered items such as dried meats, java, yeast, snacks, and nuts. In addition, Flex's new motion picture can piece of work for energy drinks packaging, vacuum insulated panels, handbag-in-box, and several other applications.

Talking about the benefits of the new film, Vijay Yadav, Business head, Flexfilms Us, said, "While developing the loftier barrier F-UHB-M, priority was given to upscale the barrier properties matching that of aluminum foil to evangelize the best packaging feel to our customers. In add-on, our teams worked extensively on creating a high value-added picture with numerous benefits and then that our converting partners gain from reduced manufacturing cost, improve operation, and achieve economies of scale while going sustainable with their packaging, at the same time."

Anantshree Chaturvedi, vice chairman and CEO, Flex Films, explains, "We are in the business of offering solutions to challenges that packaging faces and those that complement evolving market place needs. . . . . The F-UHB-M film provides the enhanced rubber parameters, the fewer complexities that convertors want, and the greener packaging that consumers seek."

Source: https://packagingsouthasia.com/type-of-article/flex-films-barrier-film/

0 Response to "Flex Films launches F-UHB-M – a metallic polyester ultra-high barrier film"

Enviar um comentário